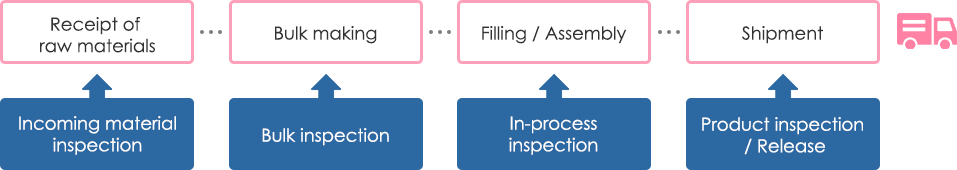

Home > Quality Control / Quality Assurance > Inspection Flow

We perform inspection to ensure that the incoming raw materials and packaging materials comply with our quality standards.

Inspection is conducted based on raw material specifications. Appearance, odor, characteristics, identification test, instrumental analysis, etc.

Inspection is conducted based on packaging material inspection standards. Functional inspection (fitting property, airtightness, etc.), appearance inspection (print contents, etc.)

We conduct tests for the bulk manufactured in plant to confirm if the bulk is made as designed. Our laboratory sets the formula of bulk and its inspection specification.

Appearance color (makeup products)

Odor

Texture

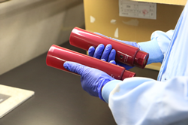

Hair dye

Appearance color (nail enamel)

Viscosity

Hardness

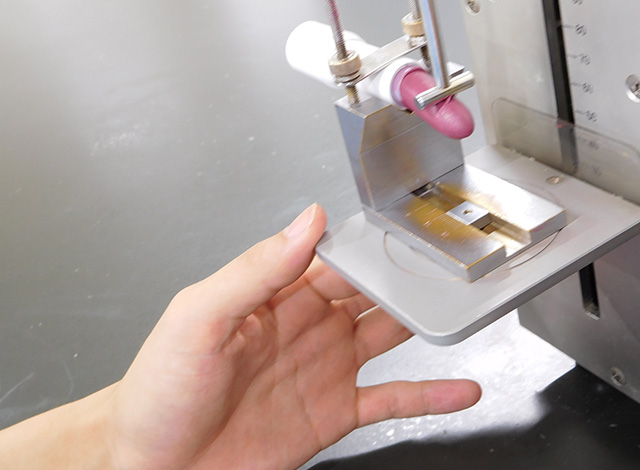

Break strength (lipstick)

Density

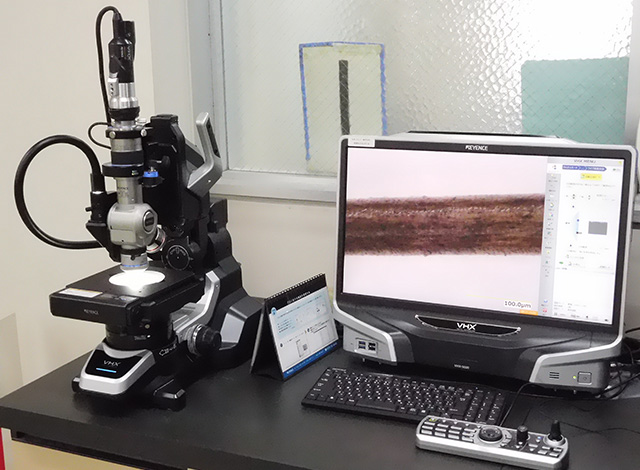

Microscope observation

High-Performance Liquid Chromatography (HPLC)

Gas Chromatography (GC)

Fourier Transform Infrared Spectrophotometer (FT-IR)

Atomic absorption spectrophotometer

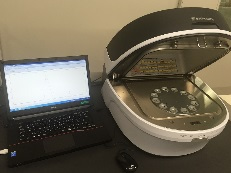

Energy Dispersive X-ray fluorescence analyzer (EDX)

Karl Fischer moisture meter

Automatic titrator

TOC meter

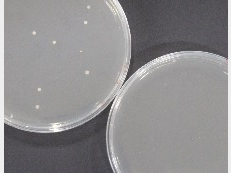

Culture

Test scene

Identification of fungus

ATP rapid tester

Autoclave

We regularly take samples from production lines to perform various inspections.

We perform product inspections on the products that are completed through manufacturing processes. Based on the product inspection results, our plant gives approval to ship the product, and only products that meet strict quality standards are shipped. We store product samples for each lot so that we can respond to quality inspection after shipment.