Home > Manufacturing Capability > Virtual Plant Tour

You can take a look of manufacturing processes of cream, lipstick and foundation

from the reception of raw materials to the shipment of finished product.

The raw materials and packaging materials required for production are delivered by suppliers.

We inspect if raw materials and packaging materials meet the specified standards.

Raw materials and packaging materials are stocked and managed respectively.

Weighing from tons to 0.01 grams, depending on production volume.

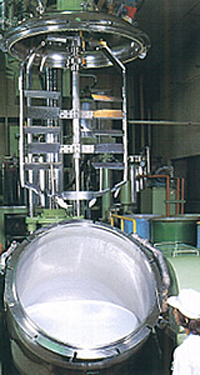

In order to manufacture products most efficiently, we select the model of production facility according to the production item and volume. (The picture is a 1300 type vacuum emulsifier)

The manufactured bulk is inspected for conformity with the standard.

Fill the bulk passed physical property measurement and microbial test into tubes.

Color is adjusted while melting and stirring the raw materials.

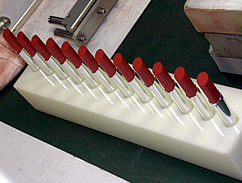

If the color tone conforms to the standard, it is filled in lipstick molds and finished to the shape of a lipstick.

Put the lipstick-shaped bulk (molded product) into the container.

Flame the surface of the lipstick with a burner to add luster.

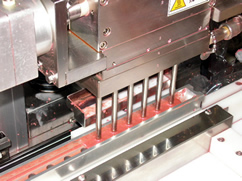

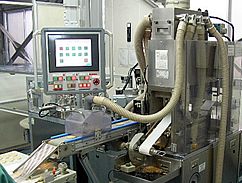

Put a label with the lot number embossed on the product and place it into an individual packaging box. The picture shows the crimping of a hanging container (blister case).

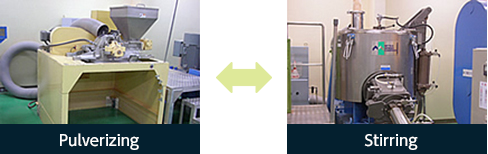

By repeating pulverizing and stirring, the particles of powder raw material are finely dispersed and stirred evenly.

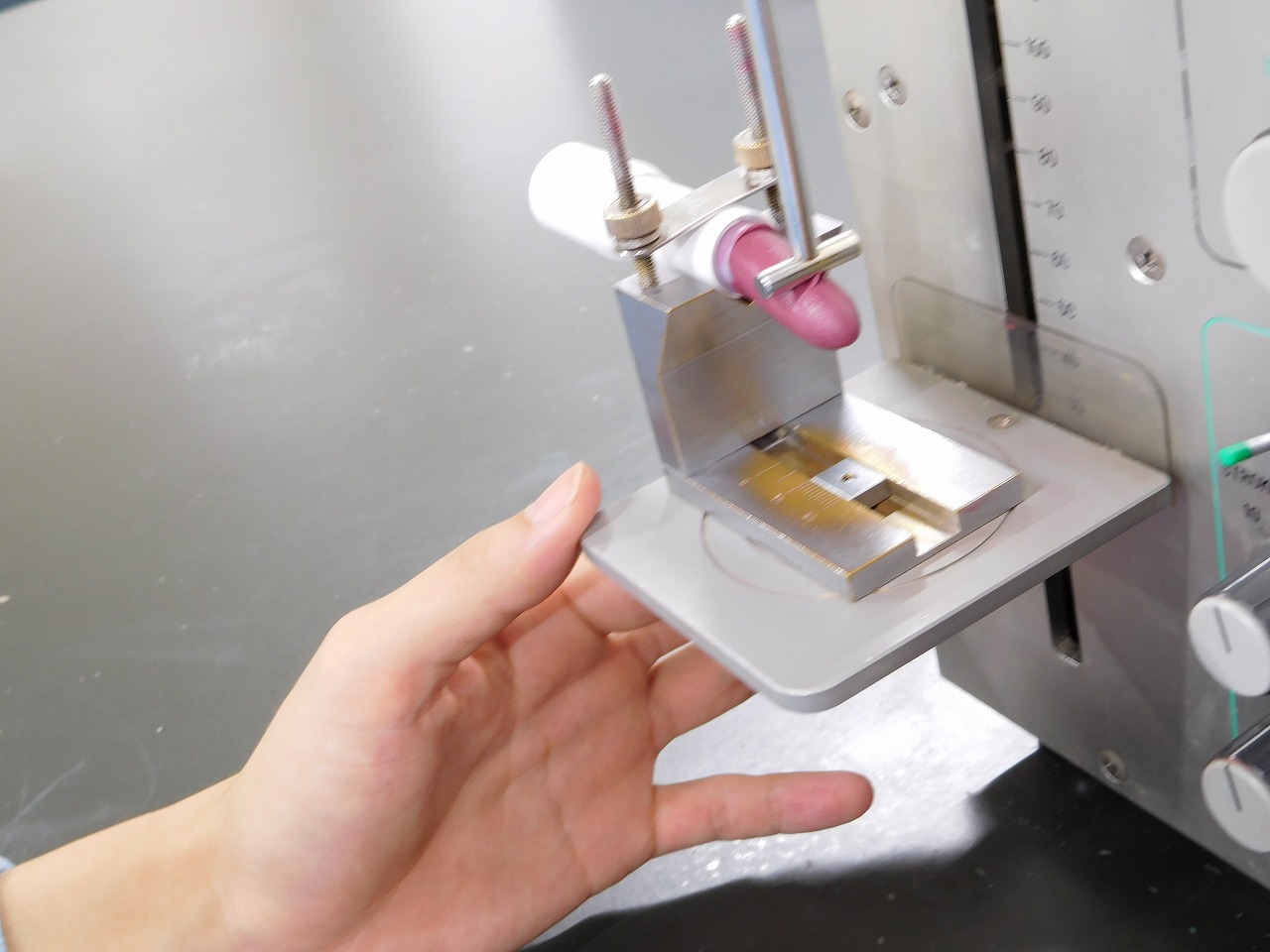

Fill the specified amount of bulk into the aluminum pan and press with a pressing mold.

Place the pressed pan into the compact and the folding carton.

We ship the finished product.